-

-

-

Loading

Loading

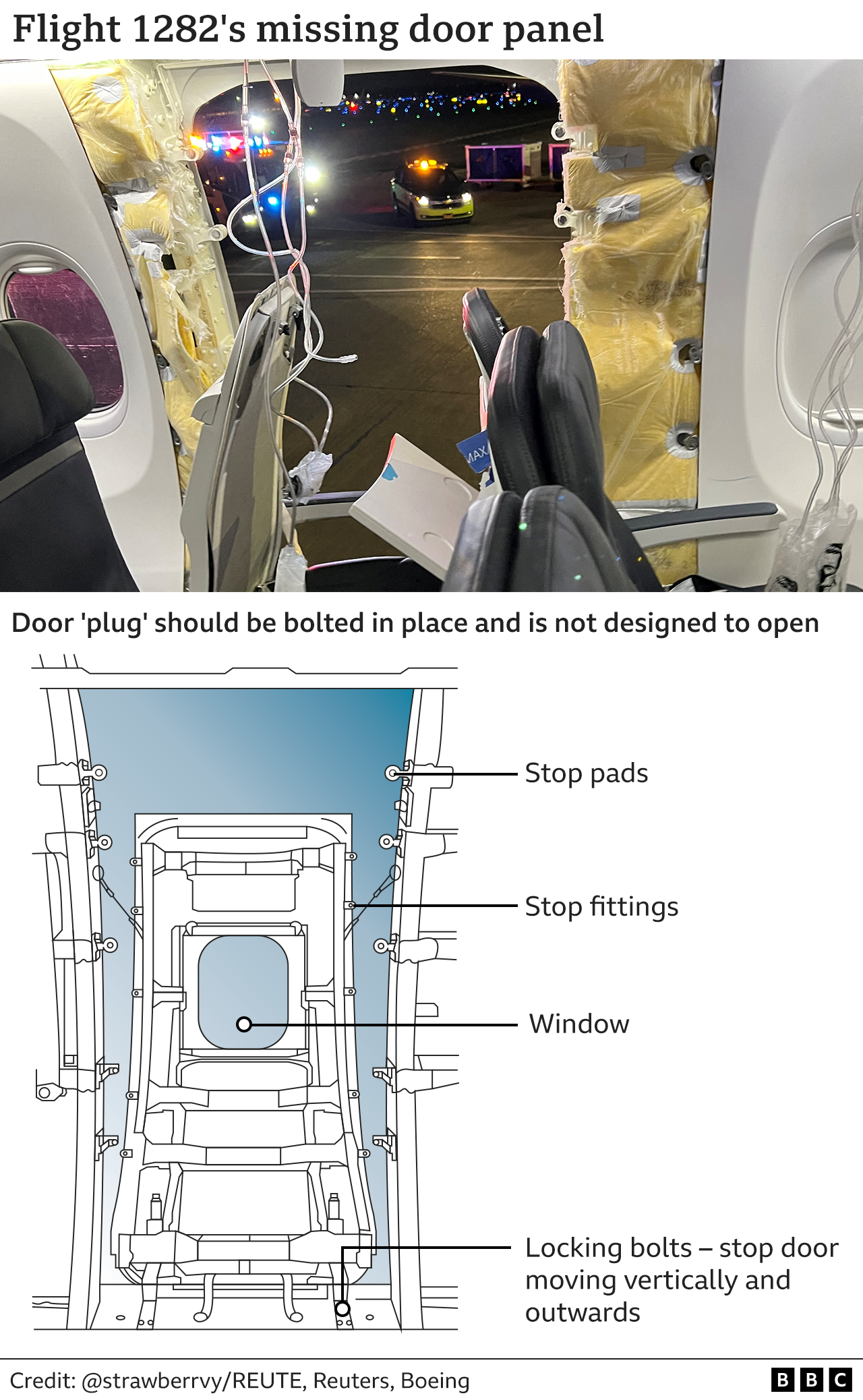

Alaska Airlines flight 1282 experienced an incident during a routine flight from Oregon to California when an unused cabin door broke away shortly after takeoff. The door plug, weighing 27kg (60lb), was part of the shell and was used to fill an emergency exit that Alaska Airlines did not require. As a result, the cabin abruptly depressurized, causing a rush of air that ripped off the flight crew's headsets and sent items flying out of the plane. The aircraft, delivered to Alaska Airlines in October 2023, had only completed around 100 flights each month, making normal wear and tear or maintenance failures unlikely to be factors in the incident. The National Transportation Safety Board (NTSB) is conducting an investigation and has stated that it does not suspect a design flaw. The door in question has been in use since 2006 on older 737s without any serious issues, shifting the attention to the possibility of a faulty door installation. The door was manufactured by Spirit AeroSystems, a supplier for Boeing, which has faced criticism in the past for quality control failures. Boeing itself has also been accused of chaotic conditions and compromised production practices. However, Boeing emphasizes that it prioritizes safety and denies any present-day manufacturing flaws. The missing door will offer crucial evidence to investigators to determine the cause of the incident. The 737 Max 9 aircraft, which has been ordered by various airlines, offers different seating configurations depending on individual requirements. The number of emergency exits required is dependent on the number of seats; while a less crowded cabin can operate with four main doors and four smaller wing exits, fully loaded configurations may require two additional exits. To accommodate different seating configurations, Boeing builds all its Max 9 airframes with extra doors. Non-operational doors, or "plugs," are fitted if they are not needed. In this case, the light that came on in the cockpit, called the "auto pressurization fail" light, indicates a rapid change in cabin pressure, which can be adjusted manually by the crew or by descending to a lower altitude. However, the warning can also stem from minor faults, as was the case with the Alaska Airlines plane, where the light had activated during multiple recent flights. Alaska Airlines had reported the issue to maintenance staff, who would follow the instructions outlined in Boeing's maintenance manual, approved by regulators. The plane was subjected to restrictions, and additional investigations were ordered but were pending at the time of the incident. Following the accident, Alaska Airlines initially grounded its entire fleet of 65 737 Max 9 aircraft, but later allowed 18 planes to resume service after completing major overhauls and inspections of door plugs. However, the Federal Aviation Administration imposed an airworthiness directive that required specific checks, leading to the grounding of all 18 planes again. The ongoing investigation conducted by the NTSB involves examining the plane, the recovered lost door, flight data recorder analysis, maintenance records, and conducting interviews with flight crew, maintenance staff, and employees of Boeing and Spirit AeroSystems. The purpose of the investigation is to identify the cause of the incident, not to assign blame. This incident poses a significant risk for Boeing, as the 737 Max is its top-selling aircraft, due to its low operating costs and fuel efficiency. However, the safety reputation of the 737 Max has already been damaged by two previous accidents resulting in a total of 346 casualties. Boeing stresses that it is a different company today and emphasizes the importance of working transparently with customers and regulators to prevent such events from occurring again.